Warenkorb

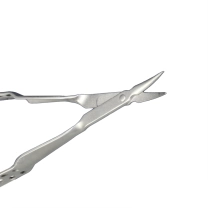

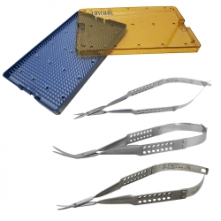

The famous SofTouch suture scissors from Laschal !

- Safely cut sutures without poking or irritating tissue

- Ball-point tips softly move tissue aside

- Enhanced tactile touch let's you know when you've located the suture

- Gently blunt-disect borders to reveal buried sutures

- Straddle suture with tips, and squeeze to cut

Ausführliche Informationen

| Marke | Laschal |

| Artikel-Nr. | MPF-N-4CXF |

| Wartung | autoklavierbar 135°C/275°F |

| Medizinisches Gerät | Class I |

| Hersteller | Laschal Surgical (USA) |

| Déclaration de conformité | CE |

Präsentation

Les ciseaux Laschal présentent une augmentation de 300% du biais de cisaillement, garantissant une coupe homogène et efficace, sans écrasement pour préserver les tissus.

Qualité

Les ciseaux Laschal sont faits d'un alliage innovant qui allège, renforce et confère plus d'élasticité à l'acier. Grâce à l'élasticité, les lames convergentes offrent un point de contact optimal entre les lames et assurent une coupe d'une qualité irréprochable pendant un nombre utilisations accru.

Atraumatique

(ref : MPF-N-4XF ou 4CXF)

Les pointes émoussées sont atraumatiques pour les tissus mous, ce qui facilite et accélère le retrait de sutures en vous évitant de passer sous le fil, en particulier pour des sutures enfouies

Ergonomie

La finesse de l'instrument vous permet de trouver vos sutures par les sensations tactiles si vous n'avez pas d'accès visuel. Enfin, l'architecture des manches liée à la légèreté de l'instrument (11 gr) confèrent un grand confort d'utilisation.

Personnalisable

Choisissez la longueur, la courbure des lames, la longueur du manche ou encore les pointes atraumatiques ou non.

Technological Advancements in Cutting from Laschal and Tri-Medics

By Dr Alan Dardik

Tri-Medics is the exclusive licensee of Lashcal Technology for the global medical market.

Dr. Alan Dardik is a consultant working directly with Tri-Medics. and also a surgeon-scientist who seeks to use the power of molecular biology to achieve a modern understanding of vascular disease, and to use the basic science laboratory to perform cutting edge research to ultimately benefit patients with vascular disease. Dr. Dardik trained at Yale, the University of Pennsylvania, and the Johns Hopkins Hospital before his appointment to the Yale faculty in 2001.

The Dardik laboratory studies the healing and function of blood vessels and synthetic blood vessel substitutes that are used in patients having vascular bypass surgery. The histologic slides prepared by the Dardik Laboratory clearly define the gross iatrogenic damage caused by the use of conventional scissors as compared to the minimalization of damage when using the Laschal/Tri-Medics scissors.

Why this technology works:

Scissors do not cut by cutting, they cut by shearing. Scissors do not initially fail because they get dull. The initially fail because they get loose. They get loose because the pressure that is created by the blades coming together in a zero degree clearance in order to 'shear' the material placed there between is greater than the resistance provided by the screw or rivet that pivots the blades together. Whatever is being cut, from the thinnest, single layered, true epithelial tissue to atherosclerotic arteries, a lateral pressure is placed upon all scissors blades which tend to separate them.

Conventional scissors must be made with a relatively narrow shearing angle between the blades because, in order to increase the edge strength, they must be hardened by a process known as heat treatment. In addition to hardening the blades, the 'heat treatment' process also reduces flexibility and makes the blades more brittle. The net effect is that the blades must be set at a very narrow angulation. If these blades were to be set at an increased angle in order to increase the efficiency of the 'shear', the blades would either 'bite' into one-another or hasten the failure of the pivoting screw or rivet. In such a scissors, a separation of the blades by as little as a .0001" (1/10,000") during surgery is enough to create margins that are 'crushed' rather cleanly cut, with the predictable results.

The Laschal/Tri-Medics scissors are made of spring stainless steel that is capable of being set at angulations that are at least 300% that of a conventional scissors. The result is that, no matter what is being cut, any lateral pressure placed upon the blades is not enough to effectively separate the blades. The ultimate result is a cleaner cut and improved surgical result.